Making ice cream might seem as simple as mixing cream, sugar, and flavor, but it’s a much more careful and controlled process, especially when it’s made for large-scale production.

Every batch needs to be safe to eat, consistent in quality, and able to withstand storage and distribution. Pasteurization is one of the most important steps in making all this possible.

Pasteurization involves heating the ice cream mix to a specific temperature for a set amount of time. This kills off harmful bacteria and pathogens that could pose health risks.

But along with food safety, pasteurization improves the mix’s texture, enhances flavor development, and helps stabilize ingredients. It ensures that every scoop, whether vanilla, chocolate, or pistachio, tastes just as good as the last.

For commercial ice cream makers, delivering a product that meets high standards and keeps customers returning for more is vital.

What is Ice Cream Pasteurization?

Ice cream pasteurization is heating the liquid mix, usually a combination of milk, cream, sugar, and stabilizers, to a specific temperature for a set amount of time.

This helps eliminate harmful bacteria and pathogens that could cause foodborne illnesses. At the same time, it prepares the mixture for a smoother, more stable final product.

The most commonly used temperatures in ice cream pasteurization are around 85°C (185°F) for 15 seconds or 80°C (176°F) for 25 seconds.

In some cases, heating the mix to 180°F for 19 seconds has proven to be as effective in reducing the bacterial count as heating it to 160°F for a longer period.

The goal is to maintain both safety and quality while preserving the natural characteristics of the ingredients.

Like milk is pasteurized to ensure safety and extend shelf life, pasteurization in ice cream manufacturing helps ensure the final product is safe to eat, has a smooth texture, and delivers consistent quality in every batch.

Whether you’re producing traditional ice cream or gelato, this step is a must to meet commercial food safety standards.

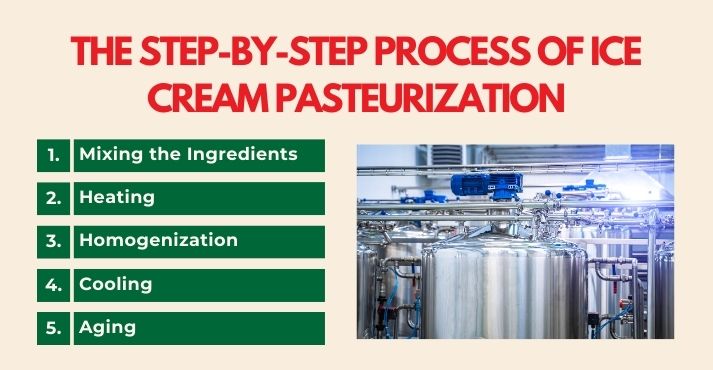

The Step-by-Step Process of Ice Cream Pasteurization

Pasteurization is part of a larger, carefully timed commercial ice cream-making process. From mixing to cooling, each step works together to create a clean, consistent base that can be safely turned into the final frozen dessert.

Here’s a quick look at how it all comes together:

Step 1: Mixing the Ingredients

Before anything is heated, the base ingredients like milk, cream, sugar, and stabilizers are measured and combined. This forms the liquid mix that will undergo pasteurization. Mixing tanks are commonly used at this stage to ensure the ingredients are thoroughly combined.

Step 2: Heating

The liquid mix is then heated using specialized pasteurizers to reach the target temperature. This could be a batch pasteurizer for smaller operations or continuous-flow HTST systems in large-scale ice cream production and pasteurization facilities.

The goal here is to destroy harmful microorganisms while preserving the natural qualities of the ingredients.

Step 3: Homogenization

Immediately after heating, the hot mix passes through a homogenizer. This equipment breaks down fat globules into smaller particles, which helps create a smooth, creamy texture and prevents the mix from separating. It’s also an essential part of the ice cream pasteurization method.

Step 4: Cooling

Next, the mixture is rapidly cooled using refrigeration equipment to bring it to safe, chilled temperatures, typically below 4°C (40°F). Quick cooling prevents the growth of bacteria and prepares the mix for the next stage.

Step 5: Aging

Once cooled, the mix is stored in aging tanks for several hours, usually overnight. This step allows the fat to crystallize and the stabilizers to fully hydrate, leading to a smoother, more scoopable texture. The aging process is essential for maintaining quality in high-end products like gelato.

Why is Ice Cream Pasteurization Important?

Pasteurization isn’t just a technical step in ice cream production; it’s essential for making a safe, high-quality, enjoyable product.

By heating the mix to the right ice cream pasteurization temperature, manufacturers can eliminate harmful bacteria like Salmonella and E. coli, reducing the risk of foodborne illness.

This matters even more in large-scale production, where food safety must be maintained across every batch.

But safety isn’t the only benefit. Pasteurization also improves the way ice cream looks, feels, and tastes. It helps fats combine evenly throughout the mix, producing better texture and balanced flavor.

Whether it’s served in a pint at home or plated at a full-service restaurant, pasteurized ice cream offers a consistently smooth and satisfying guest experience.

Consistency and shelf life also improve. How ice cream is pasteurized, from heating times to cooling processes, affects how reliably each batch performs. With fewer bacteria present, the product stays fresher longer and holds up better during storage and transport.

The Impact on Flavor, Texture, and Shelf Life

Pasteurization isn’t only about making ice cream safe to eat. It also improves flavor, creates a smoother texture, and helps the product stay fresh longer.

Flavor

Proper pasteurization allows the sugars and fats in the mix to combine evenly, which prevents off-flavors and helps deliver a well-balanced sweetness. It also neutralizes enzymes and unwanted microbes that could cause sour or bitter notes.

Texture

One of the significant benefits of pasteurization is the smooth, creamy texture it helps create. By heating and combining the ingredients, fats are more evenly distributed, giving ice cream the rich consistency customers expect in every scoop.

Shelf Life

Pasteurization helps extend the ice cream’s shelf life by eliminating bacteria and stabilizing the mixture. This makes it more viable for widespread distribution and ensures the product stays fresh longer, even in demanding commercial environments.

Variations in Pasteurization Techniques

In ice cream production, pasteurization methods can vary depending on the operation’s size and goals. Two of the most common approaches are batch and continuous pasteurization.

Batch pasteurization heats the mix slowly in a large tank, usually at around 65–85°C for ice cream pasteurization, for about 30 minutes.

Small-scale or specialty producers often use this method, as it allows for more control over small batches. Though more time-consuming and labor-intensive, it’s valued for its flexibility.

Continuous pasteurization is favored in high-volume manufacturing. Here, the mix flows through heated pipes and is brought up to the target temperature, like 85°C for 15 seconds, then cooled rapidly.

It’s faster, more efficient, and ensures consistency across large batches. However, it requires more advanced equipment and infrastructure.

Manufacturers typically choose between these methods based on production volume, cost, and the type of product they’re creating, whether it’s traditional ice cream or something more artisanal like gelato.

The Role of High-Pressure Homogenization in Pasteurization

After pasteurization, the mix goes through homogenization, where high pressure breaks down fat molecules into smaller particles. This improves the creaminess of the final product and helps keep the mixture stable during freezing and storage.

Homogenization works closely with pasteurization to ensure even distribution of fat and solids throughout the mix. This is important for achieving a consistent texture and flavor in every batch.

Equipment used for this step includes high-pressure homogenizers and combination units commonly found in commercial processing facilities and professional kitchen setups for frozen desserts.

Pasteurization’s Impact on Ice Cream Production at Scale

Large-scale ice cream production depends on consistency, safety, and efficiency. Pasteurization helps producers achieve all three by ensuring that each batch of ice cream meets the same quality and health standards.

It creates a stable base that behaves predictably during freezing, mixing, and storage, which is especially important in commercial and foodservice channels.

As operations grow, so does the need for reliable processes. Ice cream mix pasteurization supports streamlined production by minimizing contamination risks and improving ingredient stability.

This leads to fewer batch variations and a more uniform product across different production runs.

Advanced systems used in modern facilities manage pasteurization with accuracy and speed. These setups precisely handle heating, cooling, and timing, helping manufacturers meet demand while maintaining high standards.

Pasteurization vs. Raw Ice Cream Mix

Using unpasteurized mix in production increases the risk of contamination from bacteria such as E. coli or Listeria. These health hazards can compromise not only product safety but also consumer trust.

Pasteurization enhances texture and flavor by properly combining fat and sugar. This process results in a smooth, balanced product, unlike raw mixes that often produce inconsistent or grainy outcomes.

For commercial producers, pasteurization is a necessary step in delivering safe, high-quality ice cream at scale.

Global Standards and Regulations for Ice Cream Pasteurization

Pasteurization is a required step in commercial ice cream production in many countries. Government agencies such as the FDA in the United States and the European Food Safety Authority have set clear guidelines for time and temperature to ensure the ice cream mix is free of harmful bacteria. These rules help maintain food safety and public health.

Producers in Southeast Asia must follow regional food laws and international safety standards. Countries like Malaysia, Thailand, and Singapore follow food safety regulations, many of which align with international standards.

Compliance isn’t optional for manufacturers aiming to export or meet growing domestic demand, but a part of staying competitive and trusted.

With changing consumer preferences and emerging ice cream trends in the region, producers increasingly focus on making high-quality products while meeting safety expectations.

Whether dairy-based or plant-based, ensuring the correct pasteurization process helps meet local health standards and global market requirements.

How Ice Cream Manufacturers Ensure Compliance

Manufacturers monitor temperature and timing closely during pasteurization to ensure their processes meet the rules. Every batch is recorded and verified to confirm that safety targets have been reached.

Independent inspections from certification bodies help confirm that pasteurization is being handled correctly.

These reviews also check sanitation practices, including cleaning and maintaining kitchenware and equipment. This level of oversight gives retailers and consumers confidence in the product’s safety and quality.

Innovations in Ice Cream Pasteurization Technology

Ice cream production has steadily improved by introducing high-efficiency pasteurizers and automated systems.

These technologies help manufacturers process large volumes more quickly while maintaining quality and safety. Energy use is managed more efficiently, and operations run with greater precision.

Automation supports precise temperature control and continuous monitoring. This helps producers meet safety standards while delivering consistent flavor and texture across batches. Newer systems also aim to reduce water usage and limit waste during processing.

Sustainability and Environmental Benefits of Modern Pasteurization

Modern pasteurization equipment is built to reduce energy consumption and minimize environmental impact. Some systems reuse heat from one cycle to power the next, cutting down on total energy use.

Many ice cream plants use energy-efficient refrigeration and cleaner production methods to reduce environmental impact. These changes support long-term sustainability while aligning with consumer interest in responsible food manufacturing.

Conclusion

Pasteurization is essential for producing ice cream that is safe, delicious, and consistent. It eliminates harmful bacteria and helps create the creamy texture and balanced flavor customers expect.

Whether making small batches of gelato or large quantities for commercial distribution, pasteurization ensures every batch meets quality standards.

As ice cream production expands, maintaining safety and consistency becomes even more important.

Investing in effective pasteurization technology helps manufacturers control the process while complying with regulations and meeting consumer expectations. This approach supports better products and builds a stronger reputation.

For manufacturers looking to stand out, focusing on proper pasteurization is not just a wise choice, but also crucial for success in today’s market.