If your answer to the question “What is a food processor?” is that “it’s just a kitchen appliance,” you are wrong. It’s more than that. Adding a food processor to your kitchenware simplifies food preparation and expands culinary possibilities.

The Food Processor Market was worth $1.9 billion in 2023, making it one of the essential contemporary trends in hospitality equipment. If you’ve only used your food processor for chopping, it’s time to explore its other capabilities, including chopping vegetables for a quick meal, kneading dough for fresh bread, or blending ingredients for a smooth sauce.

This blog will help you discover what is a food processor and uncover the uses of a food processor to help you make the most of this innovative restaurant equipment.

What is a Food Processor?

A food processor appears at the recent edge of the evolutionary journey of commercial kitchens, designed to simplify meal preparation by handling various food processing tasks efficiently.

With every industry focusing on the automation of repetitive tasks, the hospitality industry developed a food processor to automate cooking jobs such as chopping, slicing, and mixing, which can save time and manual effort.

Whether you’re preparing ingredients for a meal or creating complete dishes, a food processor offers a wide range of functionalities.

Food Processor Uses and Functions

A food processor is an essential restaurant equipment in commercial settings. It introduced sustainability in food service equipment by significantly reducing manual labor, allowing chefs to focus on quality and creativity.

With its powerful motor, multiple attachments, and speed settings, a food processor can handle many tasks, making it a mandatory food service equipment.

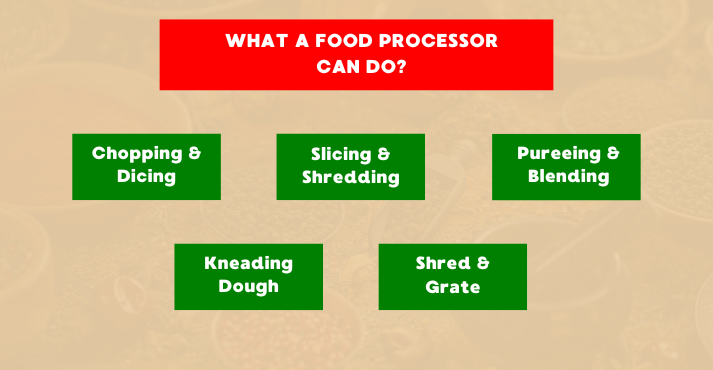

A food processor is used for:

- Chopping & Dicing – A food processor quickly chops vegetables, fruits, nuts, and meats, reducing prep time and ensuring uniform cuts for soups, salads, and stews.

- Slicing & Shredding – Precision slicing and shredding help maintain consistency in presentation and texture, which is essential for dishes like coleslaw, gratins, and garnishes.

- Pureeing & Blending – Ideal for creating smooth sauces, soups, dressings, and dips, a food processor ensures even texture without the need for excessive manual blending.

- Kneading Dough – Bakeries and pastry kitchens benefit from the dough blade, simplifying kneading for bread, pizza, and pastry dough, ensuring proper gluten development.

- Shred & Grate – Food processors can switch between grinding, emulsifying, and grating with multiple blade options, enhancing kitchen versatility.

Types of Food Processors

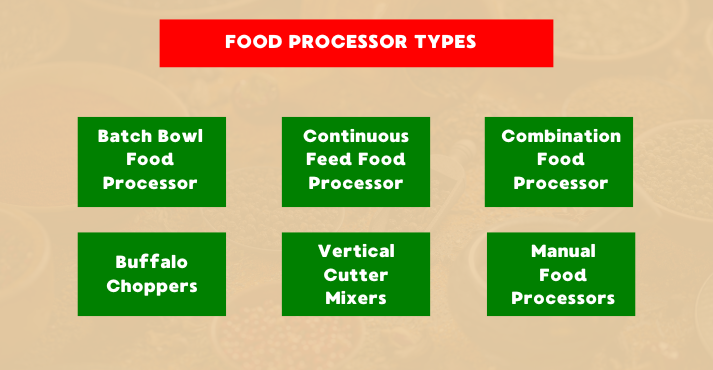

There are different food processors’ uses and functions, and they are divided into various types based on their functionality. Choosing the right type depends on the quantity and type of food being processed and the efficiency required. Here are the 6 main types of commercial food processors:

Batch Bowl Food Processors

Batch bowl food processors are ideal for kitchens with small to medium-sized batches, offering a convenient way to process and contain all finished products in a single bowl. These processors provide versatility in food preparation, allowing chefs to chop, slice, shred, grate, whip, and puree ingredients efficiently.

One limitation of batch bowl food processors is that they cannot produce precisely diced cuts like 1/2 or 3/8 cubes. The processing capability largely depends on the type of S-blade or disc used. Most models have a bowl capacity ranging from 1 to 6 quarts, though industrial versions may offer larger sizes.

Multiple bowls can be used in rotation to improve workflow efficiency, reducing downtime between batches. While plastic bowls are standard in most units, some models feature stainless steel bowls for enhanced durability, making them a preferred choice in high-use environments.

Continuous Feed Food Processors

Designed for high-volume food preparation, continuous-feed food processors are best suited for environments where a batch bowl would slow down productivity. These machines excel at heavy-duty slicing, shredding, grating, and dicing with precision, allowing chefs to process large quantities of ingredients quickly.

Unlike batch bowl models, the continuous-feed variant aids chefs in using food processors to feed ingredients through a chute or hopper while the machine runs, dispensing the processed food into a separate container. This continuous operation significantly reduces prep time, making these processors ideal for fast-paced commercial kitchens such as catering services and institutional kitchens.

A key feature of these processors is the pusher assembly, which applies even pressure to ensure consistent results. This not only improves precision but also helps reduce waste. Continuous feed food processors can achieve different cut sizes depending on the available disc and plate options, including specific diced measurements like 1/2 or 3/8.

Combination Food Processors

A combination food processor is ideal restaurant equipment for kitchens requiring flexibility and offers the best batch bowl and continuous feed models. This hybrid design allows chefs to adapt to different menu requirements and processing needs.

The batch bowl function is ideal for small-scale food prep, allowing for versatile cutting techniques such as pureeing, mixing, and emulsifying. When production needs increase, the continuous feed head allows for rapid slicing and dicing of large quantities of produce, making it a valuable tool for high-demand kitchens.

Just like other processor types, the capabilities of a combination food processor depend on the variety of S-blades, discs, and plates available. This makes them an excellent choice for restaurants, catering businesses, and food production facilities requiring precision and volume.

Buffalo Choppers (Bowl Choppers)

Buffalo choppers (or bowl choppers) are industrial-grade, heavy-duty kitchen appliances designed to chop and emulsify dense ingredients such as meats, cabbage, and root vegetables. These machines are built for durability and high production use, making them a perfect fit in butcher shops, delis, and industrial food preparation.

Equipped with strong, rotating knives and heavy-duty bowls, Buffalo choppers can efficiently process large quantities of food. Unlike standard food processors, they are specifically designed to handle harsh ingredients that require more power to break down.

Some models come with a PTO (Power Take-Off) hub, which allows additional attachments like slicers, expanding the machine’s functionality. This feature enhances versatility and makes Buffalo choppers an excellent investment for commercial kitchens that process large amounts of meat or hard vegetables.

Vertical Cutter Mixers

This food processor is used for high-capacity food processing and is ideal for bulk food preparation. These machines can chop, grind, mince, emulsify, and knead large quantities of ingredients at once, making them particularly useful in institutional settings such as cafeterias, healthcare facilities, and food manufacturing plants.

With large bowls and powerful motors, vertical cutter mixers can quickly process ingredients in large batches, significantly improving efficiency in commercial kitchens. Many models include a timer function, ensuring batch-to-batch consistency, which is critical in high-volume operations.

These processors are widely used in environments where bulk food production is required daily, such as schools, hospitals, and large-scale catering services. Their ability to quickly process large amounts of food makes them an essential tool for professional chefs managing high-demand kitchens.

Manual or Hand-Operated Food Processors

Manual food processors are a practical solution for small-scale food preparation with limited or unavailable electric power. These non-electric devices rely on hand-cranked mechanisms, pull cords, or simple lever-operated systems to perform various food processing tasks, making them reliable for kitchens with specific processing needs.

Manual food processors do not require power, unlike their electric counterparts, making them energy-efficient and portable. They are commonly used for delicate or precision-based tasks such as slicing garnishes, chopping herbs, and dicing small quantities of vegetables. Many models come with interchangeable blades, allowing users to play with desired cuts and textures.

One of the key advantages of manual food processors is their suitability for camping nights, outdoor catering, food trucks, and mobile kitchens where access to electrical outlets may be limited.

*Manual food processors are unsuitable for high-volume, commercial processing; they are an excellent choice for individuals needing a quick, efficient, and easy-to-clean tool for basic tasks.

How to Choose the Right Food Processor for Your Business

Now you understand what a food processor is, its types, and the kitchen jobs it can automate. Selecting the right food processor for your business requires careful consideration of kitchen size, the volume of food prep, and specific processing needs.

Let’s explore all the crucial factors that influence your choice of food processor.

Kitchen Size & Volume of Work

The size of your kitchen and the amount of food you process daily should guide your choice.

- A batch bowl food processor may be ideal if your business prepares trim to medium batches.

- A continuous feed food processor for high-output kitchens allows non-stop processing, reducing prep time.

- Combination models offer flexibility for kitchens handling a mix of small and large batches.

Power & Motor Strength

Motor power is crucial in commercial kitchens where frequent, heavy-duty use is expected. It is necessary to evaluate the advertised motor power of the product before buying. For instance:

- Light-duty processors (½ to 1½ HP) are sufficient for essential chopping, shredding, and pureeing.

- Medium-duty models (1½ to 2½ HP) handle larger batches and tasks like kneading dough.

- Heavy-duty processors (3 to 5 HP) are best for high-volume kitchens such as hospitals, cafeterias, and catering businesses.

Attachments & Blades

All-rounder food processors come with multiple blades and discs for chopping, slicing, dicing, shredding, and emulsifying. A model with interchangeable attachments allows you to expand its functionality, catering to a broader range of menu items. Your choice of blades can impact the texture and appearance of your food.

Speed Options & Control

Like blade types, the speed and rhythm of the motor are other crucial aspects that impact your food texture. Food processors with variable speeds and pulse functions provide greater control over texture and consistency.

*Check a device’s RPM (revolutions per minute) before buying to ensure efficient and precise cutting.

Ease of Cleaning & Maintenance

Commercial kitchens require equipment that is easy to clean and maintain. Look for models with dishwasher-safe parts and easily removable components. Wide feeder tubes help reduce prep work, and some manufacturers offer disc cleaning kits for added convenience.

Safety Features & Warranty

While choosing a food processor, ensure that the product you are buying comes with enhanced safety features to prevent accidents, such as:

- Automatic shut-off

- Magnetic safety locks

- Secure bowl attachments

Also, look for a lengthy warranty (often five years or more for the motor) to ensure peace of mind and long-term reliability. You must read the warranty terms and conditions to see the damages it covers.

Food Processor vs. Blender: Understanding the Difference

After learning all the food processors’ uses and functions, the next step is understanding how they differ from blenders. In professional kitchens, efficiency and precision are critical. Choosing the right appliance can significantly impact workflow, consistency, and food quality.

The rule of thumb is:

- Food processors excel at handling solid foods with precision

- Benders are best suited for liquids and smooth textures

But there is more detail that adds value to your choice. Let’s discover more:

Purpose: Solid vs. Liquid Processing

A food processor is designed for chopping, slicing, grating, mixing, kneading, and other tasks that involve solid ingredients. It is ideal for preparing vegetables, making nut butter, and mixing dough. Its large work bowl allows it to process dry and thick mixtures effectively.

On the other hand, a blender is primarily used for liquefying ingredients, making it the go-to appliance for smoothies, soups, sauces, and frozen drinks. Because of its tall jar and fast-spinning blades, it efficiently blends liquids and solid foods. However, it struggles with dry or very thick mixtures.

Blades & Functions: Versatility vs. Specialisation

One of the key differences lies in the blade design and functionality.

Food processors come with multiple blade attachments and discs for chopping, slicing, shredding, grating, kneading, and emulsifying. The ability to swap out blades makes them incredibly versatile for food preparation.

Blenders typically have a fixed blade at the base, specifically designed for blending and pureeing. High-powered blenders can crush ice and blend frozen fruits effortlessly, making them essential for beverages and liquid-based recipes.

*Food processors can handle some blending tasks, but they are not designed for processing large amounts of liquid, as their work bowls can leak. Similarly, blenders struggle with solid foods that lack moisture, often requiring additional liquid to function as they are supposed to.

Texture Control: Precision vs. Smoothness

Food processors offer greater control over texture, making them ideal for chopping vegetables, making pesto, or grating cheese. Chefs can achieve a coarse or fine chop without over-processing ingredients by using the pulse function.

Blenders, in contrast, are designed for smooth, uniform consistency. They break down ingredients quickly, resulting in silky soups, creamy smoothies, and emulsified sauces. When making pesto, for example, a food processor will produce a chunkier version, while a blender will create a smoother, more liquid-like consistency.

When to Use a Food Processor in a Professional Kitchen

Using a food processor in commercial settings is always recommended, where solid food items need quick and consistent processing. It is a versatile tool that reduces prep time for high-volume food production.

Since food processors allow for precise control over texture, they are ideal for scenarios where uniformity and structure are necessary. Their reliability and processing speed make them perfect restaurant equipment for high-output, commercial kitchens like:

- Fine-dining restaurants

- Catering services

- Bakeries

When to Use a Blender in a Professional Kitchen

A blender is best suited for liquid-based preparations, where ingredients must be emulsified, pureed, or smoothly blended. High-speed blenders can create fine, silky textures that food processors cannot achieve.

While blenders offer superior liquid blending capabilities, they are not suited for chopping, slicing, or processing dry ingredients in bulk. Fine dining establishments rely on blenders to create consistently smooth textures.

Conclusion

Now you understand what is a food processor. In commercial restaurant settings, both food processors and blenders have distinct advantages. Food processors have an edge over blenders in automating most kitchen jobs for someone looking for a reliable and fast kitchen appliance to process solid ingredients.

Explore FHA HORECA for more trends, tips, and tricks in the food and hospitality industry. Stay connected with us to get a chance to participate in our next hospitality equipment trade show.